This knowledge base article is a quick 3-Part Number Plate Assembly Guide using a roller jig.

You produce a 3-Part Number Plate by sandwiching printed Clear Film between a Wet-Reflective Backing and an Acrylic Face. Our British Standard certification includes number plates made with this specific plate media combination. So we can guarantee number plates made from them will be road legal, subject to correct use.

Video Guide: 3-Part Number Plate Assembly

3-Part Number Plate Assembly

When assembling a printed number plate, we recommend using a jig and roller for a professional finish. The jig pins are used to line up media accurately & consistently. And the rollers apply equal pressure across the entire width, helping the adhesive to bond evenly. Below is a quick step-by-step guide to 3-Part Number Plate Assembly.

Place Your Printed Film on the Jig

To start, place your jig in a well lit, clean and warm work area. Use the pins and place your printed clear film face up on the jig. Ensure it’s positioned flat and square.

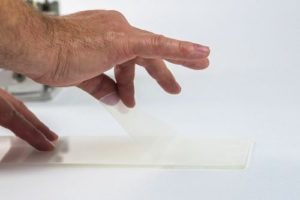

Peel Back & Crease the Adhesive Cover

Next, you’ll stick a clear acrylic face above the printed film. So, fold back a few centimetres of the adhesive cover at the right side of the acrylic. Create a crease in the cover to stop it from slipping back onto the exposed adhesive.

Join the Acrylic Face & Film

Now line up the acrylic face with the adhesive side facing down, towards the film. Use the pins to help ensure the sides all match up. Carefully join them together at the exposed adhesive end, by running your finger lightly down the edge.

Roll and Bond Them Together

Slide both parts towards the rollers, with the joined edge nearest. Take and keep hold of the folded adhesive cover on the Acrylic Face. Slowly wind the Jigs arm, so the components are fed through. The adhesive cover should pull off while the rollers bond the parts together.

Next, Prepare the Wet Reflective

Next place your wet reflective sheet face up onto the jig, ensure it’s positioned flat and square using the pins. Just like the acrylic earlier, fold back and crease a few centimetres of its adhesive cover.

Join Acrylic & Film to the Reflective

Now position the joined Acrylic & Film above your wet reflective. The clear film side should be facing down towards the reflective. Next, carefully join the parts together, run your finger lightly down the edge.

Roll and Bond the 3-Parts

Slide the components towards the rollers, with the joined edge nearest. Take and keep hold of the folded adhesive cover on the wet reflective. Slowly wind the arm, so the components are fed through. The adhesive cover should pull off while the rollers bond the parts together.

Remove the Acrylic Faces Cover

Finally, remove the protective cover from the Acrylic Face’s non-adhesive face. Remember to wait a few minutes after assembly, for the glue to cure before handling or fitting to a vehicle.

3-Part Number Plate Specification

We hope this 3-Part Number Plate Assembly guide & YouTube Video provides a quick refresher. Try this 3-Part Number Plates Article for more details on the plate components, its specification & recyclability.