CLS700 Operational Conditions

This knowledge base article shows the recommended CLS700 operational conditions. We use two of these large printers in our Core Elite system because they produce extreme volumes of number plates, with minimal interaction. Plus they provide a more robust plates system, less susceptible to cooler conditions.

If you follow the recommendations set out here, you’ll have less print issues with your plate production. And you’ll end up with better quality number plates.

Citizen CLS700 Printers

Each Citizen CLS700 thermal printer we provide is modified with settings that require some basic conditions be met. For the best printing results, only operate them in locations where the following temperature, humidity and dust levels are met. Diverting from our recommendations can effect the print quality and thus the legality of your finished number plates.

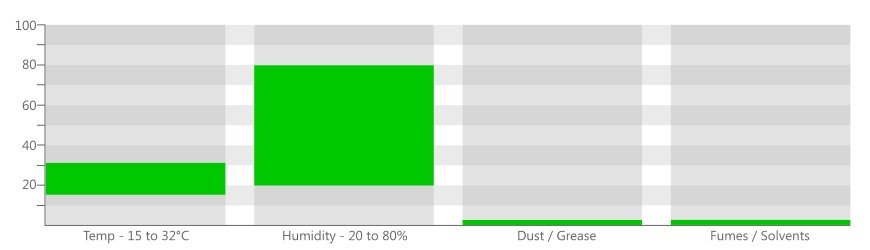

Environmental Conditions

These settings are based on information from the printer manufacturer and results from our own internal testing with Reflective Rolls.

- Temperature: 15 to 32°C

- Humidity: 20 to 80% relative humidity

- Dust: Dust particles may contaminate prints

- Fumes: Some fumes & aerosols can effect prints

- Assembly: 20°C and above

These thermal machines are more robust than laser printers, so they can be used in slighter cooler locations. Dust, grease and some airborne fumes can still present a risk to print quality by contaminating components or sticking to the print-head. So carry out your plate production away from the workshop or garage.

Some components, especially those already coated with adhesive, may require room temperatures of just over 20°C when assembling. We acknowledge that conditions in some summer and autumn months may be more forgivable regarding temperatures and humidity levels.

Operating Space

Enough space should be provided all around these printers for ventilation and to access the machine. For instance, these are front output machines, so you will need room for prints to emerge. Place the printer on a flat desk or worktop large enough to accommodate it and at a height comfortable for you to operate. And don’t neglect your plate assembly area, especially when using a roller jig.

Component Storage

Store all your plate media components in a dry, warm place away from excessively bright light. To avoid contamination from dust leave them in their packaging until required and then take them out and install immediately. For best results wipe your reflective & clear acrylic with a lint free cloth before using them. And we recommend cleaning the print head regularly, while changing the ribbon or before a production run.

Need Help?

For more detailed instructions, try your number plate system’s user guide. Or for help with your settings contact our customer service team. And remember, you can order CLS700 Printer Consumables from our online np-shop.